The Power of AI Inventory Replenishment for Fashion Retailers

Suffering from inventory issues like product surplus or stockouts? Does replenishment planning feel like a game of catch-up? Fashion brands and retailers are often deeply affected by a wide range of variables, ranging from supply chain issues to current events. Adding to the intensity of the situation is the fact that few consumer industries move as quickly as fashion or have as many factors applying pressure and creating continuous unpredictability.

But surprisingly, many retailers still get stuck using sluggish tools, if any, when it comes to merchandising, pricing and inventory. In early 2023, McKinsey published a piece illustrating how generative AI will benefit the fashion industry, citing examples in design, marketing and sales where artificial intelligence could analyze and use predictive learning to plot out everything from designs to inventory optimization.

If your teams are still relying on instinct, guesswork and manual spreadsheets, there are better, more intelligent options to leverage large quantities of data. AI tools can quickly enable teams to create effective demand predictions for optimized product allocations, stock re-balancing and inventory management.

Let’s dive into the basics…

What is Inventory Replenishment?

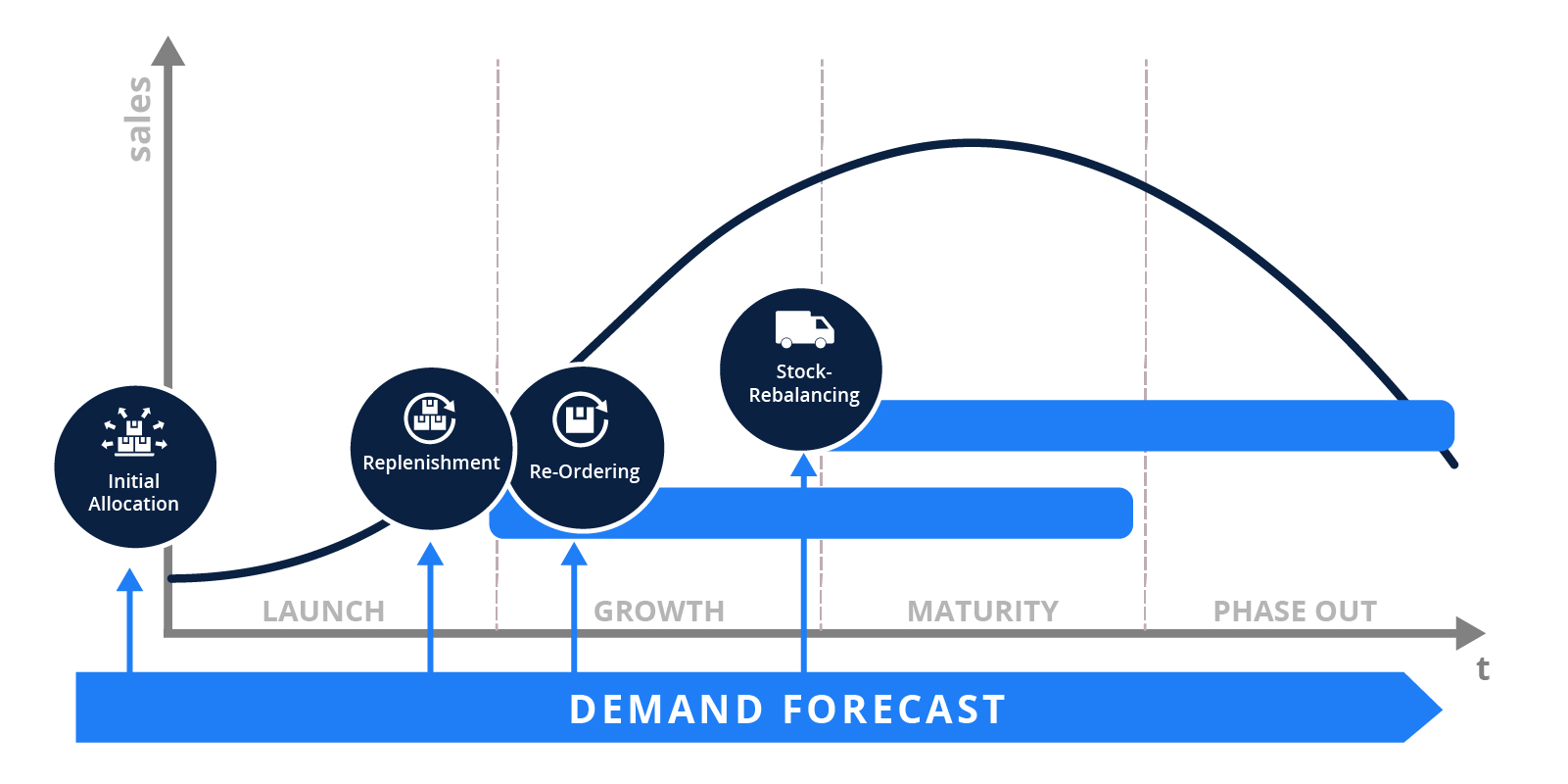

Inventory replenishment is primarily concerned with the movement of products and is a systemic approach that ensures proper stocks levels are maintained. This process includes a focus on transitioning products from storage areas to sales spaces, while procuring new inventory batches from manufacturers. This system prioritizes meeting customers’ demands, ideally without experiencing stockouts or overstock issues. Maintaining optimal inventory levels is tied to the strategic goals of a company, like the need to clear inventory come the end of the season by placing the right products in the right places. Doing that also leads to the reduction in discounting and selling more items at full price.

How Does Inventory Replenishment Work?

To maintain the leanest, most profit-centered retail operations, businesses need to have a robust and strategic replenishment plan in place. This not only ensures that there’s no disruption in sales due to stock unavailability but reducing the problem of overstocking and keeping inventory levels optimum in turn reduces working capital.

With advancements in technology, businesses are increasingly moving towards automated stock replenishment systems that utilize AI to predict stock requirements, re-ordering and re-balancing for every product. This creates greater efficiency, while minimizing manual work which is incredibly time consuming and error prone.

Methods of Inventory Replenishment

Retailers employ various strategies and methods to ensure their inventory replenishment is effective and efficient. Some of these methods include:

This method involves moving stock from sales spaces to storage during slower periods. This ensures that there’s always ample stock during peak sales times without overburdening the sales space of brick-and-mortar locations. This method is, however, not without its shortcomings. Without precise demand forecasting, the top-off method can lead to excess inventory or understocking, as well as increased handling costs and failure to respond to unexpected fluctuations in the market or seasonal demand changes.

Rather than continuously adjusting stock levels, some businesses prefer restocking at regular, predetermined intervals. This method simplifies the replenishment process and makes it more predictable and autonomous. However, it also requires robust and accurate forecasting to be effective. A miscalculation in the forecasting process could set in motion poor inventory performance. The inflexible nature of this approach means replenishment may not align with the realities of the market. Without real-time tracking in place, a brand can be left unprepared to react and capitalize on trends and changes in demand.

Properly balanced inventory includes rebalancing stock, which involves regularly evaluating and adjusting stock levels based on current sales data along with future forecasting. However, this balance can be a challenge for fashion brands and retailers to maintain. Keeping a higher quantity of stock than necessary often results in overstocking, which leads to increased holding costs, the need for discounting and potential wastage. On the other side of the pendulum, understocking can cause both missed sales opportunities and customers to look to competitors, with the added risk that those customers never return.

Demand forecasting, also known as demand prediction, is the process of anticipating customer demand using historical sales data, market trends and other relevant factors. It enables businesses to prepare for peaks and troughs in sales. While this typically would involve manual analysis of spreadsheets and historic data, the risk is that spreadsheets cannot take into account a range of external, influencing factors that would affect the demand of a product, some of which could include weather, events, price, promotions and so on. Creating accurate demand forecasts for 1000s of product SKUs across categories, channels and locations along with all these complexities in a spreadsheet is simply impossible.

There are multiple types of forecasting which focus on different time spans and markets. For instance, macro forecasting looks at larger market trends, while micro forecasting hones in on specific product demand. In addition, short-term forecasting predicts demand for a shorter duration, like weeks or months, while long-term forecasting anticipates demand often spanning years.

What are the Challenges of Inventory Replenishment?

Without optimization tools, businesses face mounting challenges when it comes to proper inventory replenishment due to a number of pressure points and variables. These often include:

- Lower demand than expected: Overestimating demand, buying too deep and overstocking products, because of inaccurate demand forecasts, ties up working capital in unsold, low-demand products that then need to be discounted heavily in order to sell and clear inventory at the end of the season.

- Limited warehouse space: Physical space can be a limitation, especially for growing businesses, making optimal stocking a necessity.

- Costly store transfers: Allocating and replenishing goods in the wrong places either means heavy discounting to clear stock or costly store transfers which also increase a company’s carbon footprint.

- Re-ordering products with short and long lead times: Fashion companies are renowned for new product introductions mid season. Re-ordering must take into account shelf and distribution center capacity, order and lead times, minimum order quantities and packing requirements. All of which are complicated when working with highly seasonal assortments and changing trends.

- Getting initial allocation right: This refers to the initial supply of new and seasonal articles which if done manually is most often based on outdated plans. This initial allocation must also take into consideration warehouse and store eligibility.

- Knowing when to holdback: Deciding when it’s necessary to avoid surplus, it might make sense to hold back part of the delivery. Ideally this should take demand analyses, logistics and handling costs into account.

- Reducing waste to fit sustainability initiatives: If inventory replenishment means supply does not meet demand, it can leave retailers with excess stock and waste. In a time when more and more customers are being eco-conscious, this is another factor brands need to consider. Among the array of carbon-reducing options, minimizing waste may be one of the most easily attainable for fashion brands.

What is Inventory Optimization?

Inventory optimization is the strategic approach that businesses employ to ensure that they maintain the ideal stock levels, allowing them to meet consumer demand without the pitfalls of dead stock or experiencing product shortages. In essence, it’s about striking the perfect balance, ensuring you have just the right amount of stock at any given time, without overproducing and eating into revenue.

What are the Benefits of Inventory Optimization in Retail?

As profit margins shrink and the retail marketplace becomes a more crowded, challenging landscape, inventory optimization offers a way for brands to gain a competitive edge where few exist. The current retail landscape has experienced significant shifts in recent years with the speed of customer demands continuing to accelerate, sustainable initiatives maintaining importance and the desire for new and trendy mid-season product introductions unrelenting. All of which complicate efforts for effective inventory management. Tools that work towards optimization are however, enabling companies to work toward benefitting the bottom line.

Some of these benefits include:

- Reduce operational costs: By ensuring that only the necessary inventory is held, retailers can cut down on storage and holding costs.

- Prevent overstocking: Holding excess stock ties up capital and can lead to increased wastage. Inventory optimization ensures you stock what you sell.

- Re-balance stock: Regular stock evaluations ensure that product distribution is balanced, catering to all sales channels efficiently.

- Better customer satisfaction: Meeting customer demands promptly leads to better reviews, repeat purchases, and the cultivation of brand loyalty.

- Reduce the need for discounting: By placing the popular items in places they will sell means teams have to discount less.

- Clear inventory: between meeting customer demand, shifting stock from one store to another where it will sell and ensuring the right products are in the right place for customers ensures higher inventory clearance at the end of the season.

At this point in our digital era, teams cannot afford to waste time, money and effort manually analyzing spreadsheets or making intuitive forecasts. Today, more fashion brands and retailers are turning towards inventory optimization solutions, relying more heavily on the ability of AI to make informed decisions, analyze huge amounts of data, accurately predicate demand and fulfill it.

Gain a Competitive Edge with Intelligent Inventory Optimization Solution

A comprehensive solution like Centric Software®’s newest solution, Centric Market Intelligence & Inventory takes historical company data along with external influencing factors to accurately predict the future demand for every product, in every channel in every location. Further leveraging AI and automation then optimizes allocation, replenishment and re-ordering to fulfill demand.

Centric Market Intelligence & Inventory offers an inventory optimization solution designed to mitigate the most common pitfalls of replenishment planning, forecasting and allocation through the powerful capabilities of AI. It automates and optimizes the entire process, taking over as a planning solution from the moment products are in transit. Inventory replenishment begins at optimizing the initial allocation of goods, the subsequent re-ordering of popular items, stock transfer and replenishment.

Not only does this speed up the replenishment process but it also drives greater accuracy in an often error-prone process. With enhanced supply chain visibility thanks to Centric’s single source of truth, businesses can quickly track their inventory in real-time from the manufacturer to the retail shelf. By employing machine learning algorithms, businesses can quickly predict sales trends with greater accuracy, allowing them to adjust their stock levels with confidence.

Centric Pricing & Inventory™ leverages predictive pricing and inventory automation to optimize both across various stages of the retail life cycle. Unlike other solutions in the market that are limited by their rule-based constraints or lack transparency, Centric Market Intelligence & Inventory transparent predictions enables the user to see and accept the projected outcomes and recommendations. In this way it multiplies the effect of human efforts by automating a large portion of the work and therefore allows teams to cover more SKUs – in fact it can automate both pricing and inventory for an unlimited number of SKUs in any channel, country and store.

Ready to say goodbye to the days spent manually sifting through spreadsheets full of SKUs, historical data, external factors, store capacity, lead times and so on when developing replenishment plans. Say hello to a user-friendly, intuitive solution that delivers on inventory optimization, has strong, impactful and quick ROI and sets businesses up with the competitive edge needed in today’s market.