What is Product Lifecycle Management (PLM) and PLM Software?

Product lifecycle management, also known more commonly as PLM, is the strategic process of managing a product’s lifecycle from ideation, development to sales and even end of life. PLM drives an eco-friendly and ethical business model, streamlining production, reducing errors and empowering effective team collaboration, ultimately saving time and money; a strategy that’s vital for all consumer goods companies around the world.

Essentially, any company that makes multiple products at once – with people collaborating across different offices, countries and timezones – uses a product lifecycle management process in some way or other.

Today, the term ‘product lifecycle management’, typically refers to the software, the backbone technology that drives all product-related activities from concept to retail.

What is PLM Software?

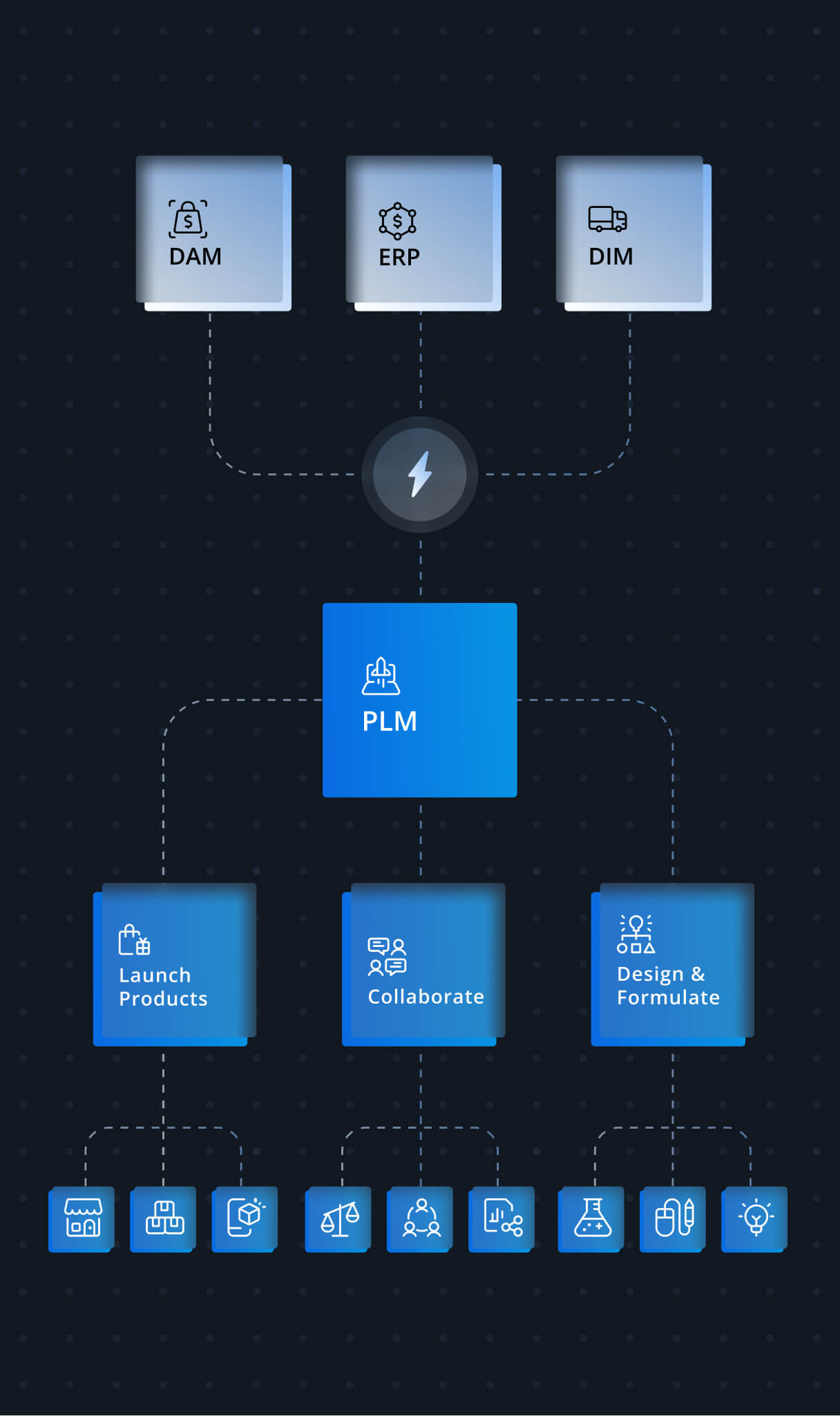

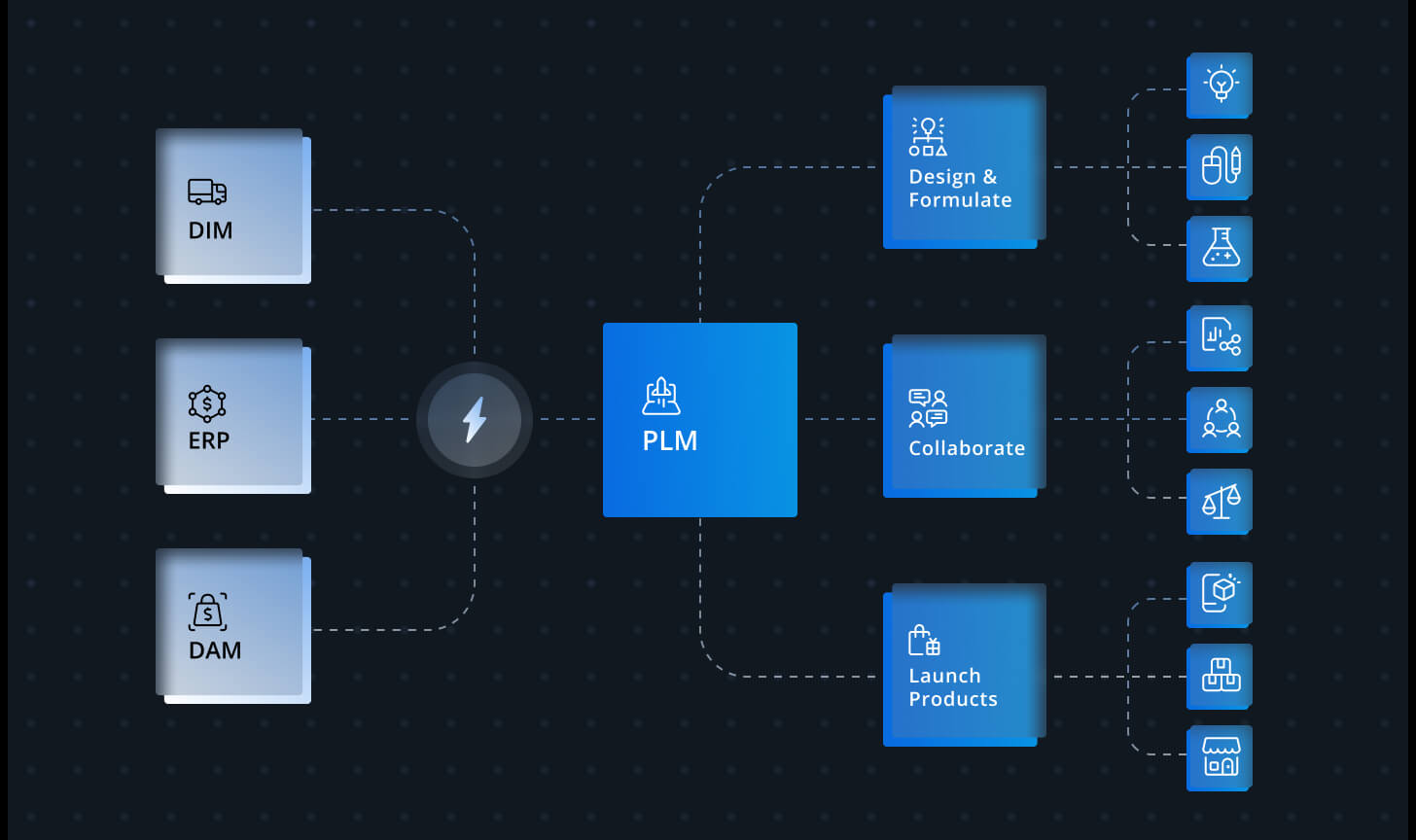

PLM software is a solution designed for end-to-end product development that empowers companies to boost innovation, modernize their businesses, streamline product development and simplify collaboration. PLM software is a ‘single version of the truth’ for real-time product-related data that connects people, products and development across the entire product lifecycle allowing you to develop products with one single platform.

As consumer and market demands have evolved, PLM software has also changed to meet the needs of businesses to accommodate product development and business growth. Today, modern PLM solutions are more agile tools that have taken over its on-premise predecessor.

The History of PLM

PLM originated in the automotive and aviation industries, which required a software platform that could track and manage complex and highly regulated products with thousands and thousands of manufactured parts and people. Today, driven by increasing design and manufacturing complexity, globalization and competition, PLM solutions are employed in many industries developing, producing and selling fast-moving consumer goods.

Fashion and retail were the first consumer goods sectors to be impacted by digital transformation catalysts such as e-commerce. Today, PLM has been adopted beyond the Fashion and apparel industry including:

- Outdoor & Sports

- Multi-Category Retail

- Home & Furniture

- Food & Beverage

- Consumer Goods

- Cosmetics & Personal Care

DID YOU KNOW: According to Design News, the first recorded product to launch using a PLM was the Jeep Grand Cherokee. This has been a best-selling car since it’s launch in 1992!

If you’re familiar with Product Development Management (PDM), PLM is an expansion of a PDM as a need developed for more data to be shared. When technology improved and the internet came into common use, PLM evolved into a reality and Product lifecycle management software was developed.

What is a Modern PLM System?

A modern product lifecycle management system is one that is cloud-based, completely configurable and is easily accessible from anywhere in the world – via a PC, laptop or mobile.

Cloud-based PLM software automatically updates product changes, advancements and industry compliance regulations in real-time. This means businesses no longer need an IT department to carry out updates and integrations, freeing time to allow teams to do what they do best — creating products.

Cloud-based PLM software brings efficiency in ensuring products get to market faster, track data and processes that allow you to achieve higher product margins all from the cloud.

What are the Benefits of PLM Software?

Implementing the right technology is essential for a variety of businesses reacting to marketplace fluctuations who not only want to recover successfully but go on to thrive in the new climate. Many brands are revolutionizing the way they ideate, produce and sell products by incorporating a tool, such as PLM software, that acts as the digital backbone that enables them to capitalize on three key drivers:

- Agility

- Efficiency

- Innovation

PLM software provides companies with the agility required to manage complexity, scale as needed, and meet consumer demand while also adapting in the face of unexpected change. PLM allows product traceability, speeding product development as collaborators working across different offices, countries, languages and time zones can collaborate effectively as errors, due to poor communication, are eliminated. PLM software can also boost innovation as real-time consumer data can be integrated into the solution to develop new products.

When we generated our first tech pack there was this moment where everyone was really proud of what we’d accomplished.

- Reduction of errors: Keeping track of all of the product information becomes challenging when software like excel, emails, dropbox, servers, and PowerPoint, which typically leads to chaos. Having a PLM, streamlines workflow visibility into all product-related data eliminating work duplication, reduces the number of emails, meetings and phone calls as well as time spent searching for or updating information.

- Improved collaboration and communication: With internal teams and external partners all over the world real-time data and workflow capabilities are essential. PLM allows collaborators to make timely adjustments and supports integrations with external databases creating a ‘single source of truth’. Maintaining a single source of real-time factual data can increase working efficiency, improve product launch success rates and continue to improve sales performance.

- Improved strategic decision-making: Investing in technology and boosting efficiency empowers teams to innovate and create, all while working towards common business goals. Whilst teams can focus on value-added activities like channeling efforts into producing high-quality products, PLM becomes more than just a software platform, it’s the step to digitally transform your business and go-to-market strategies.

- Speeds time to market: PLM gives access to product details that simplify business processes, improve supply chain collaboration and decision-making capabilities, along with innovative applications, such as 3D proofing and review processes, companies can bring products to market faster. Utilizing this visibility allows businesses to spot time-wasting and costly risks and take action to keep products flowing.

- Increased revenue and better product quality: PLM software allows businesses to quickly and accurately calculate relationships between cost, profit and price changes according to set sales goals. Suppliers can be added to the supply chain collaboration process in advance, allowing global procurement to be managed in a unified manner to determine the best procurement plan and thus improve product profitability.

- …and much happier people!

Who uses PLM Tools?

Industries: PLM systems are a powerful solution for businesses like retailers, brands, DTC, manufacturers and producers that face design and manufacturing complexity, globalization and the need to develop and move goods fast! As we’ve evolved into our ‘new normal’ with the increase of remote working at an all-time high, companies need a tool that promotes collaboration across internal employees and external partners regardless of their location. Investing in the right PLM tool will help businesses take control of their future.

A wide range of industries and businesses leverage PLM for agile production. According to the 2019 PLM Market Industry Analysis report, the following industries use PLM tools:

- Aerospace and defense (A&D)

- Automotive and other transportation

- Electronics and high-tech (Electronics, high-tech, high-tech consumer devices, semiconductors; Telephony/satellites/electro-mechanical; and Medical devices)

- Fabrication and assembly (Industrial machinery and heavy equipment; Consumer goods, white goods, other discrete goods; Retail, footwear, and apparel)

- Process/consumables (Pharmaceutical; Consumer packaged goods, including food and beverage)

- Process/bulk chemical

- Utilities

- CIS (Construction, Infrastructure, Shipbuilding)

- Other (financial and investments, insurance, and services)

In-house teams: Every team, department and function at every level of your company benefits from a PLM system. The centralized software streamlines and facilitates core processes across your company, allowing all personnel to creatively share and obtain accurate product data in real-time. PLM makes it possible to get a wider variety or products to more markets and more channels faster. This improves the efficiency of internal and external collaboration and accelerates the speed of product launch whilst effectively reducing costs. It is no surprise that a PLM tool is becoming one of the core ‘foundation’ systems for companies in all industries.

External teams: PLM also drives robust and secure platform collaboration with suppliers, factories and vendors and any other external stakeholders like agents and freelancers. Businesses can share ‘need-to-know’ information with ease, and vendors can manage data input themselves, taking this time-consuming task off your to-do list.

PLM System Capabilities and Use Cases

A PLM system has a number of capabilities and use cases to aid the production process. To name a few some of the key use cases are listed below.

A PLM tool allows you to design in real-time whilst new data is being added to the system simultaneously. This process speeds up time-to-market as the final product is on-trend with consumer insight. Which in turn can significantly increase revenue, boost innovation and track consumer behavior.

Product portfolio management is a continuous, data-driven process that allows retailers and manufacturers to decide what products should stay or go, increase or decrease in cost, or require updating to meet consumer interests. PLM tools allow businesses to optimize product portfolios effectively on a large scale as full visibility and a comprehensive overview of the entire product development process is provided.

Bill of materials (BOM) is a list of items needed to create a product which is a key aspect in a PLM solution. Incorporating BOMs into a PLM tool allows businesses to collaborate from the point of product conception through to manufacturing by connecting the correct sourcing details, manufacturing information, compliance regulations and so on, in real-time. As a result, you reduce the risk of errors, increase efficiency, decrease cost of waste and speed time to market.

Engineer to Order (ETO) requires a collaborative process as customer input is vital for the product requirements. A PLM tool for ETO provides a solution that enables you to be able to share product information with the sales team, engineers and operations team alike. This single source of truth allows all internal and external stakeholders access to consumer trends, market data and customer satisfaction which are core elements of product success.

Data collected from internal stakeholders, suppliers, manufacturers and consumers can then be utilized to speed time to consumer at the most cost-effective price. Resulting in consumer retention, employee efficiency and product development.

Real-time collaboration is the number one strategy to help companies address sourcing challenges, such as regulations issues. Companies need a way to easily deal with compliance challenges, factory audits, vendor compliance, vendor scoring and quality assurance. A PLM system allows companies to maintain updated

Whilst companies adopted new business models and become more globalized, supply chain strategy consequently has had to evolve. With a PLM tool, the supply chain process can be streamlined allowing companies to manage each component of the process to suit buyers’ needs and regulatory requirements. Resulting in higher quality products and accelerating time to market.

A PLM can help you speed time to market whilst lowering costs due to its collaborative nature. Providing traceability during the production process in real-time allows internal teams and external partners to be able to follow the correct workflow.

The phase after a product has been manufactured is called Product information management (PIM). A PLM tool allows integration with a PIM system to provide information on distribution and service products that can be distributed to the relevant stakeholders. PLM provides an effective system to be able to communicate the most accurate product data in a timely manner to push the product from engineering to market.

Producers and manufacturers require access to every last bit of information needed for product development. Product formulation software provides a data-packed roadmap, including raw material and recipe data, R&D documentation, regulatory text and manufacturing process operations. Integrated with a PLM system it enables users to enhance the formulation process, reinforce regulatory compliance, full raw material traceability, healthier margins and future product innovation.

Which industries use Centric’s PLM software?

Traditionally, brands and retailers have been the largest adopters of Centric PLM™ Software. However other industries have adopted the system as they manage similar product information and want to streamline operations by digitally transforming their business processes. Now with over 500 companies, covering more than 2000 different brands, Centric’s solutions are driven by the most innovative companies in the world, paired with industry best practices and modern technologies like 3D, mobile apps, digital boards, AI and more.

Currently, Centric PLM is used by the following industries:

Centric Software offers a fully SaaS cloud-based solution that’s robust and comprehensive covering all aspects of product development allowing teams to innovate anywhere and find the information they need – whether that be from a desktop PC or a mobile device. Centric’s innovative mobile solutions allow information to be captured outside of the scope of traditional systems encouraging innovation with real-time reactivity.

Centric’s cloud-based PLM provides a unique Agile Deployment implementation offering a highly configurable solution, with a user-friendly interface that can be configured for different roles or structured according to your unique business goals in the fastest time to value.

Centric PLM has facilitated digital transformation for companies streamlining operations and enabling efficiencies for faster time to market. Even though industry-specific data that they handle vary, the goal is the same; to get the right product delivered to market on time, at the right price and at the highest quality.