Unlocking Potential

Robyn McCarthy, Global Merchandising Manager at Silver Jeans Co.™, remembers how the company used to operate back in 2010. With the product development, design and operations departments using a variety of different outdated software solutions and tools, teams found it difficult to access the information they needed when issues arose.

“We were getting by with the tools and programs that we had, but we didn’t have one central location for all of our data. It was preventing us from using our assets to their full potential and we were wasting resources on the whole.”

“As a business quickly growing and expanding into other regions around the globe, we found this lack of visibility and communication had an impact on how we worked,” she explains. “Our key users were on the go, traveling all the time to every corner of the world and they needed the ability to access data no matter where they were.”

Eight years later, Silver Jeans team members across the world collaborate in Centric PLM™, sharing real-time information in a centralized, cloud-based digital system. The business has cut sample lead times by 25%, doubled its number of product lines since 2010, and reduced production lead times by 10% since the latest version upgrade.

How have Silver Jeans Co.™ and Centric Software cultivated a productive long-term partnership that gets results?

Denim in Demand

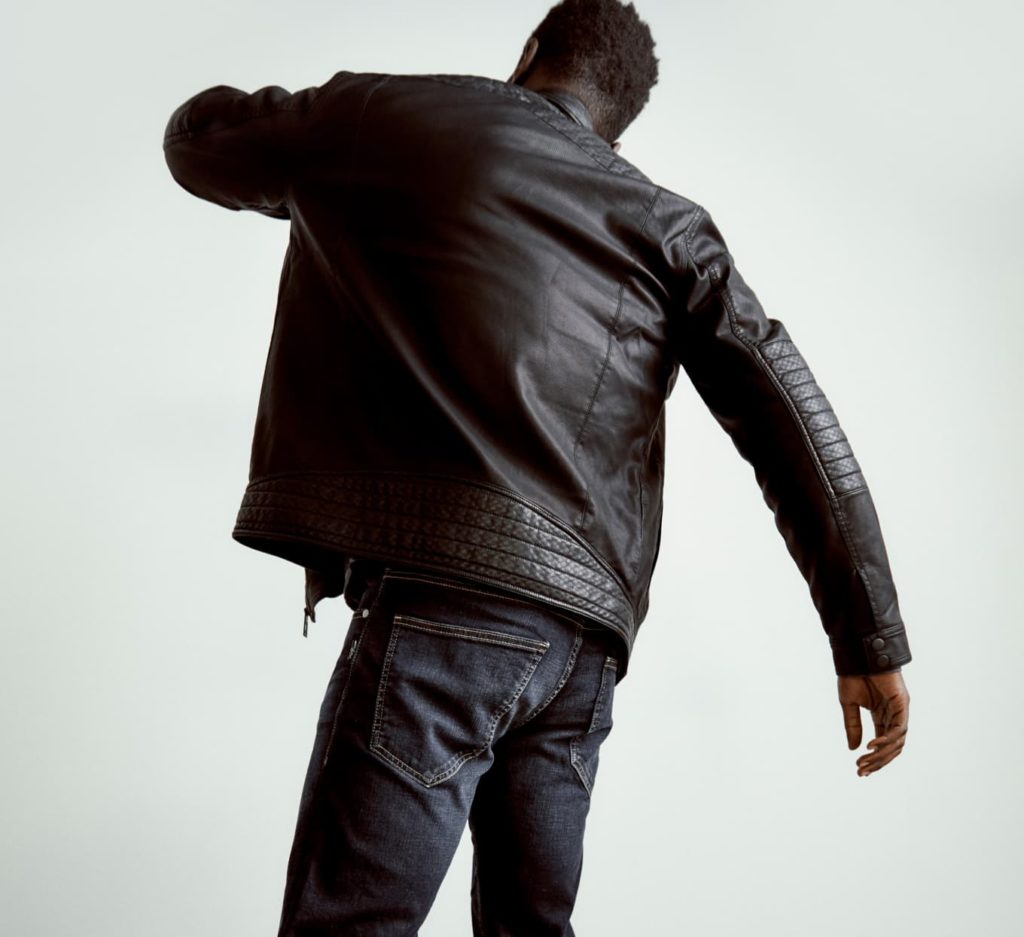

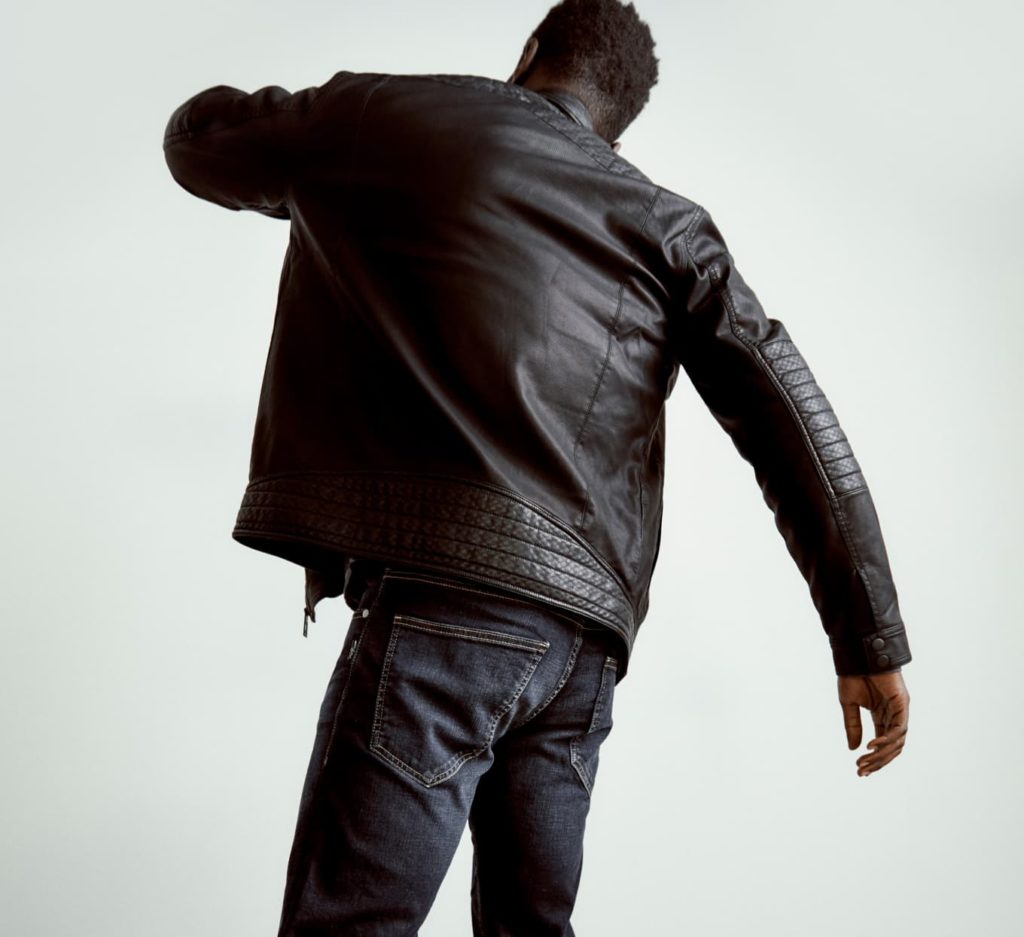

Silver Jeans Co.™ is headquartered in Winnipeg, Canada and evolved from a denim manufacturer into a successful global jeans brand. In 1991, Michael Silver founded Silver Jeans Co.™ as an extension of Western Glove Works, originally founded by the first generation of the Silver family in 1921.

Silver Jeans Co.™ launched its first ‘Frisco’ unisex bootcut jeans in 1991, going on to sell over 2 million pairs. An updated version of the Frisco was recently re-launched into Silver Jeans Co.’s women’s line, with a selection of leg openings from straight to skinny. With an emphasis on fit, unrivaled attention to detail and pride in their denim workwear heritage, Silver Jeans Co.™ makes clothing that is built to last.

Today, Silver Jeans Co.™ has six offices across Canada and the USA as well as a factory center in Hong Kong, and sells through distributors in Europe, Japan and Australia. The business operates on a four-season basis and develops 100- 200 SKUs per season across its six lines: Men, Big and Tall, Women, Plus, Sportswear and Maternity.

Silver Jeans Co.™ was an e-commerce pioneer, opening its online store in 2003 and is a crucial pillar of the business today.

Robust PLM to Support Business Goals

By 2010, Silver Jeans Co.™ had outgrown its existing software solutions and ways of managing product development.

“With multiple people handling data, there was no direction and ownership wasn’t clear when something needed to be addressed,” says McCarthy. “We wanted to increase the number of products but had no clear way of managing that process. It became obvious that we needed a program that would help us to achieve our company goals.”

“We knew that PLM would enable us to centralize information, which was critical. We also knew that the solution would have to be robust in order to manage our growing business and expansion into other lines, but flexible enough to implement change and new processes as we continued to grow.”

After thoroughly examining leading PLM vendors in the marketplace, Silver Jeans Co.™ settled on a relatively young contender at the time: Centric Software. Silver Jeans Co.™ first implemented Centric PLM in 2010 and has been through several solution updates since then.

A Long-Term Relationship

As McCarthy says, “Centric PLM was at the top of our list for many reasons. With their industry expertise, and specifically their focus on the garment industry, they understood our needs best. Working with a company that fit with the friends and family culture at Silver Jeans was very important to us. Centric employees are great to work with and have a dedicated support person for each company, which is key because they get to know our processes and are quick to produce solutions.”

“As Centric is cloud-based, it can be accessed from anywhere around the world. It’s extremely user-friendly and has consistent functions which are the same across all the sections of PLM, so there is no guesswork when looking for the information you require. Everyone is working in one central system. This cuts employee time spent on tasks to minutes, when it could have taken hours or even days previously. The out-of-the-box implementation without requiring any customization was huge for us, as it allowed us to move very quickly.”

Centric PLM was initially implemented in just 12 weeks and as McCarthy emphasizes, the subsequent upgrades have been a very seamless process.

“We’ve been working with Centric PLM for many years now and have gone through several migrations. Each of these was on time, on budget and met our business targets. Personally, I believe that engaging in a migration is an exciting venture, not something to be scared of. It has benefited the business every time.”

Cutting Time With Centralized Data

Silver Jeans Co.™ has reported impressive results since implementing Centric PLM and continues to discover new benefits as features are added in each upgrade

“We’re able to pull all resources into one central location, from costing to sourcing, production information to quality assurance,” says McCarthy.

People have live, up-to-the-minute data wherever they are, from our offices in North America to our factories overseas. We currently work with about ten factories, as well as trim suppliers, and we’re able to source information from all those vendors and maintain it in one place.

As she continues, “It was a seamless transition from our old PDM and Excel-based systems. It has streamlined our reporting functions, allowing all of our teams to make better decisions about products at all levels of our organization. The benefit with Centric is that we can do all this ourselves with the solution’s out-of-the-box functionality. Reporting that used to take days now takes minutes.”

Since implementing Centric PLM, Silver Jeans Co.™ added Sportswear, Big and Tall and Maternity to the original trio of Men, Women and Plus. Following the upgrade to v6.2, production times have been reduced by 10%, allowing the company to react faster to in-season requirements.

“Materials libraries and drop-down menus make it easier to compile BOMs and tech packs, reduce errors in communication with factories, and give users easy access to information they need,” says McCarthy. “While our main use of PLM is in product data packages, Centric helps to keep all departments organized and on track. This includes our executive and accounting departments, who don’t work in PLM on a daily basis. Sharing information has become so much easier.”

Innovative Future

Centric’s commitment to incorporating customer suggestions and feedback in every new version, as well as involving customers in the process of innovating new solutions, is a key reason why Silver Jeans Co.™ looks forward to each PLM upgrade.

New to Centric PLM? Learn more

Centric AI Fashion Inspiration Learn more

What is Centric Planning? Learn more

Demand Planning Learn more

Assortment Planning Learn more

Allocation and Replenishment Learn more

What is Centric Pricing & Inventory? Learn more

What is Centric Market Intelligence? Learn more

Centric Visual Boards Learn more